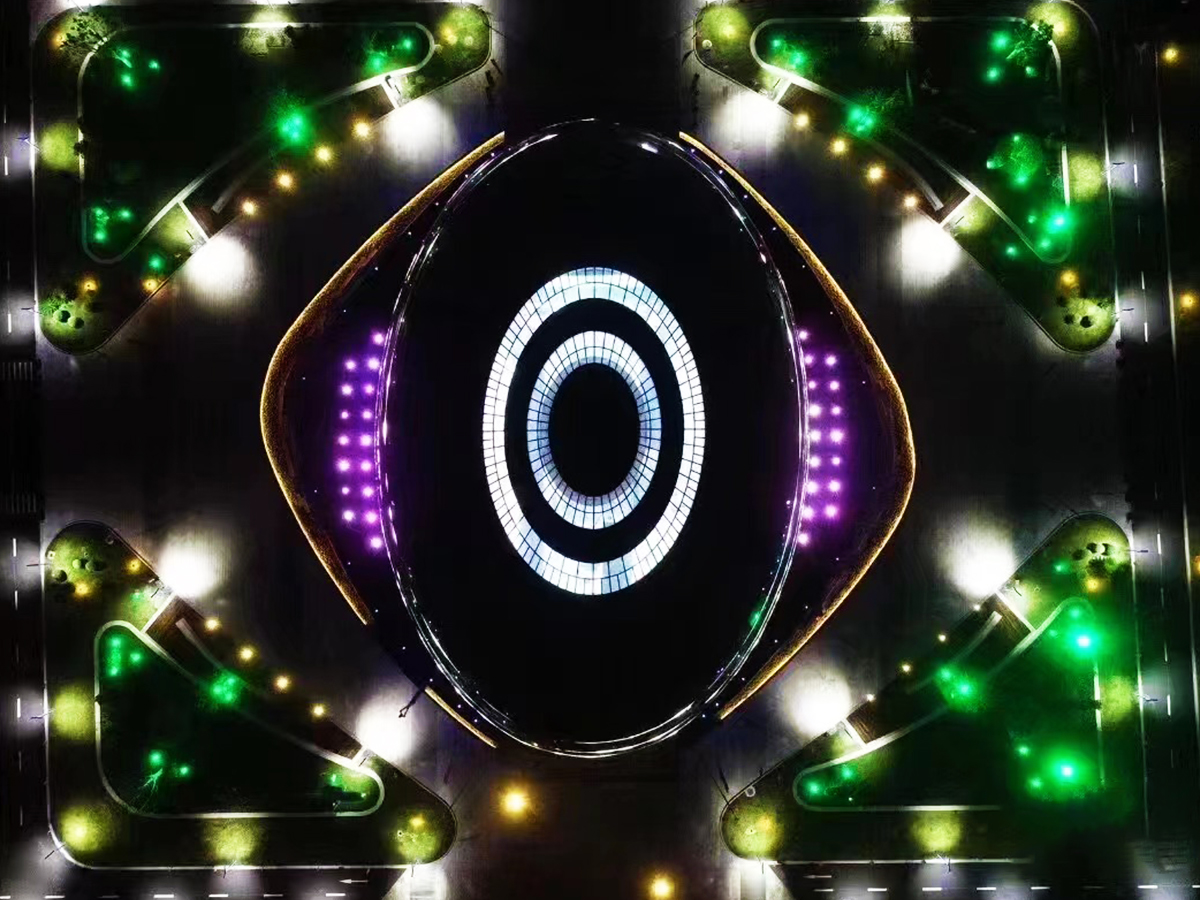

This prefabricated 3D steel pipe truss is a high-performance structural solution independently developed by Jiangsu Andy Steel Structure Co., Ltd. It is designed to meet the strict construction standards of large-span buildings such as stadiums and exhibition halls. The product adopts advanced automatic welding technology and high-quality steel raw materials, which can achieve maximum structural strength and stability while minimizing on-site construction procedures. It has become the preferred structural material for projects such as the Singapore Tennis Stadium and badminton halls due to its lightweight, high durability and flexible assembly characteristics. The truss system breaks through the limitations of traditional building structures, effectively shortens the construction period, and reduces the overall project cost, making it an ideal choice for modern large-scale construction projects.

The product is widely used in the construction of badminton halls, tennis courts, gymnasiums and other sports venues. Its three-dimensional structural design can provide a large and unobstructed indoor space, which meets the layout requirements of sports venues. At the same time, its high corrosion resistance ensures a long service life even under high-frequency use conditions.

For exhibition halls and terminal buildings, the flexible composition advantage of this steel pipe truss is fully reflected. Daylighting roofs and large doors can be installed at any position, which can improve the lighting effect of the building and the convenience of cargo and personnel flow.

It is also suitable for the construction of special-shaped buildings with unique appearance design and large-scale storage warehouses. Its stable structure can resist various external environmental impacts and ensure the safety of the stored items.

Parameter Type | Specific Specifications |

Material | Mild Steel; Stainless Steel |

Coating | Spray Painting; Galvanization; Powder Coated |

Color | Blue; Green; Dark-gray; Client's Request |

Steel code | Q235-B; Q345-B; Stainless steel |

Fabrication | Advanced Automatic Welding Machines |

Quality control | GB/T19001-2000----ISO9001:2000 |

The truss system adopts a three-dimensional design, which has strong load-bearing capacity and good structural stability. The appearance is concise and beautiful, which can be perfectly integrated with various architectural styles.

The product uses high-quality steel materials and professional coating technology, with a service life of up to 50 years. It has excellent anti-rust performance and can adapt to various harsh environmental conditions.

The prefabricated design realizes the integration of factory production and on-site assembly, which greatly shortens the construction period. Doors and daylighting roofs can be installed flexibly according to the actual needs of the project.

The product has the advantages of low transportation cost and simple installation process, which effectively reduces the overall cost of the project. It can be applied to various types of buildings and has strong versatility.

Raw Material Inspection: The inspection is divided into three links: warehouse inspection, quality inspection and test inspection. The warehouse staff will check the name, specification, model and quantity of the raw materials. The quality inspection department will conduct sampling inspection on the physical and chemical properties of the raw materials. Test samples will be taken for trial production to ensure that the performance meets the requirements.

Finished Product Inspection: Before leaving the factory, the finished products must pass four inspections: packaging inspection, identification inspection, appearance inspection and performance test. Unqualified products will be reworked until they meet the standards.

Jiangsu Andy Steel Structure Co., Ltd. is a professional manufacturer integrating R & D, design, production, construction and supervision. The company has a workshop covering an area of more than 100,000 square meters and is equipped with advanced production equipment and software systems. The annual production capacity reaches 36,000 tons, which can meet the large-order needs of customers. The company has a professional technical team, which can provide customized design services according to the specific needs of customers.

- 7*24 Hours After-sales Service: The company has an excellent after-sales service team, which can respond to customer problems in a timely manner and provide solutions at the first time.

- Customized Technical Design: The professional technical team can carry out personalized design according to the customer's project needs and site conditions to ensure that the product is perfectly matched with the project.

Are you looking for a high-quality, cost-effective steel structure solution for your stadium or large-span building project? Contact us now! Our prefabricated 3D steel pipe truss will bring you an efficient and stable construction experience. Click the "Inquire" button to get the latest quotation and detailed project plan. We are looking forward to cooperating with you!